Production Process

At Ruf Guitars, our production process is a seamless blend of advanced engineering, cutting-edge materials, and meticulous craftsmanship. Every guitar we create undergoes a journey that prioritizes innovation, precision, and individuality, resulting in an instrument that stands out in both performance and design.

Check out the factory tour

USA Facility

We have officially opened a new Ruf Guitars Custom Shop in Maryland USA.

Why? Because more than half of our guitars already go to the U.S. and Canada.

It’s time to get even closer to the people who inspire us the most — our players.

Don’t worry — our workshop in Poland isn’t going anywhere. But with this new location, we can diversify production, expand our product lines, and introduce new models and finishes made right here, in the States.

Right now there are 2 models available to order from our US Custom shop. Check out our Models section for more info!

EU Facility

Step into our main facility in Warsaw, Poland, where we build most of our production. Take a behind-the-scenes tour, meet the dedicated artisans crafting your dream instruments, and test our instruments in our Showroom.

Our main factory is also a home for all other brands of RUF Technologies family, like Hiscox Cases and RUF QC.

If you're interested in visiting us - let us know via e-mail and let's meet!

.jpg)

Advanced R&D and Composite Theory

The foundation of our process begins with intensive research and development, where we combine engineering principles with an in-depth understanding of acoustics and material science. Through extensive testing of resonance frequencies, damping factors, and mechanical properties, we developed Ruffaine, our proprietary composite material. This custom mix of epoxy resin ensures superior tonal consistency, acoustic excellence, and mechanical stability.

We also focus on zero-waste production, recycling carbon fiber scraps into forged carbon finishes, creating both aesthetic and sustainable solutions. This meticulous R&D drives every step of our process, ensuring that innovation is at the core of every guitar we produce.

Carbon Fiber & Composite Construction

At Ruf Guitars, aerospace-grade carbon fiber is the cornerstone of our instruments. Layers of carbon fiber are molded with precision to form a seamless body and neck, delivering unparalleled strength, lightweight performance, and climate resistance. Paired with Ruffaine, this construction eliminates the inconsistencies of traditional wood, ensuring repeatable quality and state-of-the-art performance.

Luthier Expertise

Our team of master luthiers brings decades of experience, having crafted instruments for some of the most iconic names in the music industry. Each guitar is meticulously shaped, assembled, and set up by hand to ensure optimal playability and tone. Their expertise ensures that every Ruf Guitar is not only a technical marvel but also a true musician’s instrument.

Robotic Precision and RufQC

We integrate robot-assisted manufacturing to achieve unmatched precision in key stages of production, such as shaping, finishing, and assembly. This technology ensures that each component is crafted with micrometer-level accuracy. However, every instrument undergoes RufQC, our proprietary quality control system, combining robotic precision with human inspection by our luthiers. Every guitar is tested extensively for stability, tonal consistency, and mechanical reliability before it leaves the workshop.

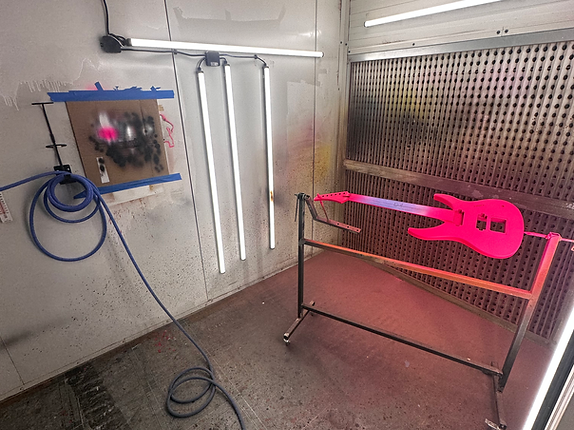

Finishing and Customization

The finishing process at Ruf Guitars is where art meets technology. From painted finishes and cloth tops to wood veneers and carbon designs, each guitar is tailored to the player’s vision. Whether it’s a sleek gloss finish or a custom relic effect, every detail is executed with perfection.

A New Era of Guitar Craftsmanship

Ruf Guitars are the result of a production process that balances innovation, sustainability, and craftsmanship. By combining advanced materials, pioneering R&D, and the expertise of our luthiers, we create instruments that set a new standard for performance, aesthetics, and reliability. Every guitar we make is more than an instrument—it’s a work of art built for the future of music.

.png)